Calibrated needles for creating leaks

These piercing tools for flexible packaging play an essential role in quality control and leak testing of flexible packaging (pouches, bags, multilayer films).

They create precise calibrated leaks with diameters ranging from 30 to 300 microns, thereby reproducing actual leak defects (micro-cracks, defective welds, perforations) in a controlled manner.

Available in all standard sizes and adaptable to your specifications, these tools are also used to determine the optimal test parameters: by piercing a reference sample, they generate a known leak and allow you to determine the test parameters for your test bench (vacuum, helium or tracer gas detection, differential pressure, pressure drop), thus ensuring the reproducibility of measurements and compliance with standards such as ISO 11607 or ASTM F2096.

If you would like more information about these tools, please do not hesitate to contact us.

Patches and septums for internal pressure testing: ASTM F2096

These patches, also known as septums, are specifically designed for internal pressure testing. They are specially designed to adhere properly to the packaging under the specific conditions of the test. They can withstand immersion for several minutes and allow you to test your samples under the best conditions.

They are available in packs of 250, 1,000 and 5,000 units.

If you would like to order these patches, please do not hesitate to contact us.

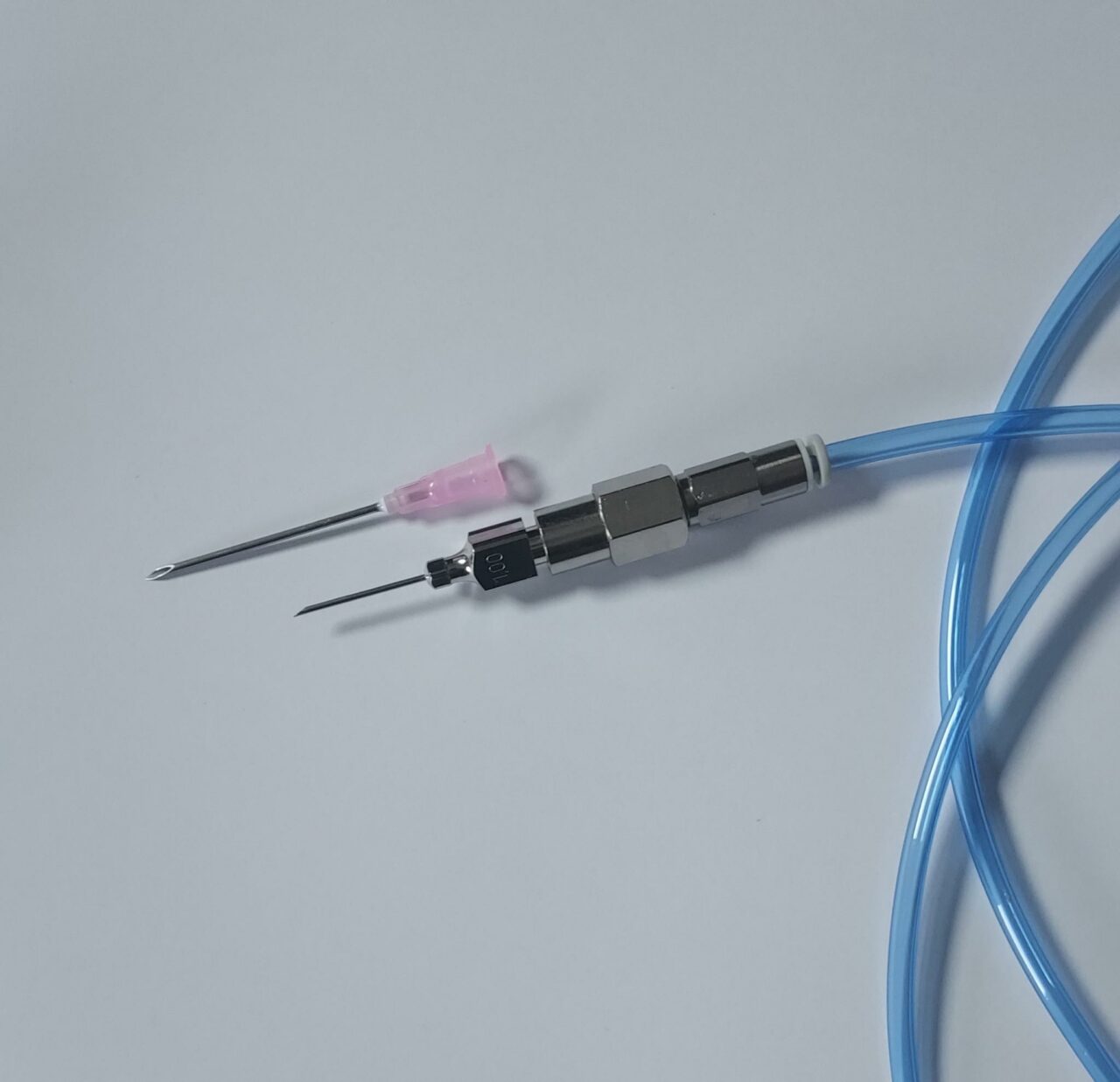

Advanced needle kit for ASTM F2096

This needle kit was manufactured in our workshops and specially developed to be practical and allow for easy needle replacement. It allows the packaging to be pierced through a waterproof patch and pressure to be injected inside the packaging.

During ASTM F2096 testing on products that can clog the needle, it is important to be able to change the needle easily so as not to block the use of the kit.

This kit is therefore equipped with a LUER-LOCK connector and a 4 mm diameter pneumatic connector.

The kit is compatible with most needles available on the market. We supply the kit with two needles, one with a metal base and the second with a plastic base.

Complete metrology kit for vacuum chamber.

Easily check all your vacuum sensors annually with our comprehensive metrology kit. Designed for vacuum leak testing, this kit accurately checks your vacuum measuring devices (0 to -1 bar).

Why check your sensor annually?

ISO 9001 compliance and test reliability: An incorrectly calibrated sensor will distort your leak test results (detected or hidden leaks).

Complete package :

- Reference gauge: 0.1% full scale accuracy

- Universal connector kit for enclosure

- Carrying case

- Calibration procedure included

Need to calibrate your vacuum sensors?

Contact us now for this professional metrology kit.

Oil mist filter for vacuum pump

Lubricated vane vacuum pumps can generate slight fumes when operating at high loads. For certain industries with stringent requirements, these fumes may be a criterion for rejection.

These filters, which are positioned at the exhaust, capture this oil mist and significantly reduce the generation of these fumes.

They are equipped with a filter cartridge and a reservoir that collects the oil captured during operation. The reservoir has a drain and must be emptied regularly.

The filter cartridge inside the filter can be replaced when it becomes too clogged with oil and no longer performs its filtering function.

If you are interested in this type of filter, please do not hesitate to contact us.