Bottles, flasks, vials, trays... we have the right solution for your packaging.

The tightness of packaging containing liquids is essential to enable the liquid inside to be transported and consumed in the best possible conditions.

Are you encountering problems when transporting your packaging? Leaks, products arriving at their destination empty or leaking...

There are several solutions available

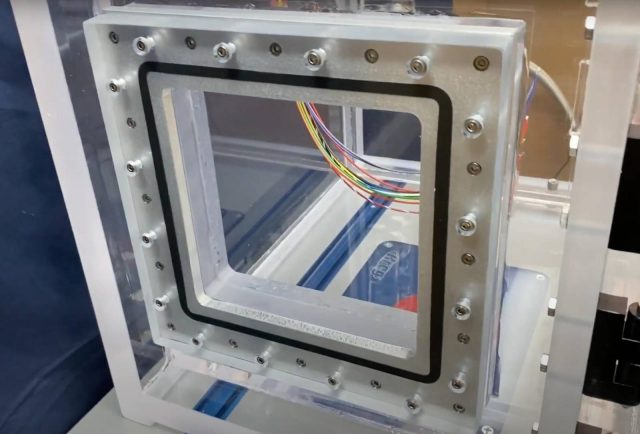

Our vacuum chambers can be used to test your packaging under optimum conditions:

- Dry vacuum test to detect leaks

- Transport simulation to analyse the behaviour of your packaging during air or road transport.

- Analyse the overall behaviour of your packaging when subjected to external stress.

These tests can help you understand the cause of your customer feedback. They can also help you validate a new material on your production line.

Our team of experts will guide you towards the best solution for your specific needs.

Leak detection on empty packaging

Dry or immersed, bottles and other rigid containers can be tested to validate their leak-tightness.

Tests can follow the recommendations of ASTM D5094 or ASTM D3078.

The sample is subjected to a pressure difference that allows stresses to be applied to the sealing elements: plugs, stoppers, etc. The operator can visually check what is happening: bubbles in the case of an immersion test, or flowing liquid in the case of a dry test, etc.

Leak test on filled packaging

Our vacuum chambers can also be used for extensive testing of empty rigid containers.

These tests can follow the recommendations of ASTM D4991, for example.

In this method, the container is subjected to an extreme level of vacuum to check for strength and leakage.

This test is performed in immersion.

Customised study

Your needs are specific, you don’t follow a particular standard but you have adapted the protocol to your product…

We adapt our housings to your needs:

- specific dimensions,

- extreme vacuum level,

- pass-through to power your product during the test…